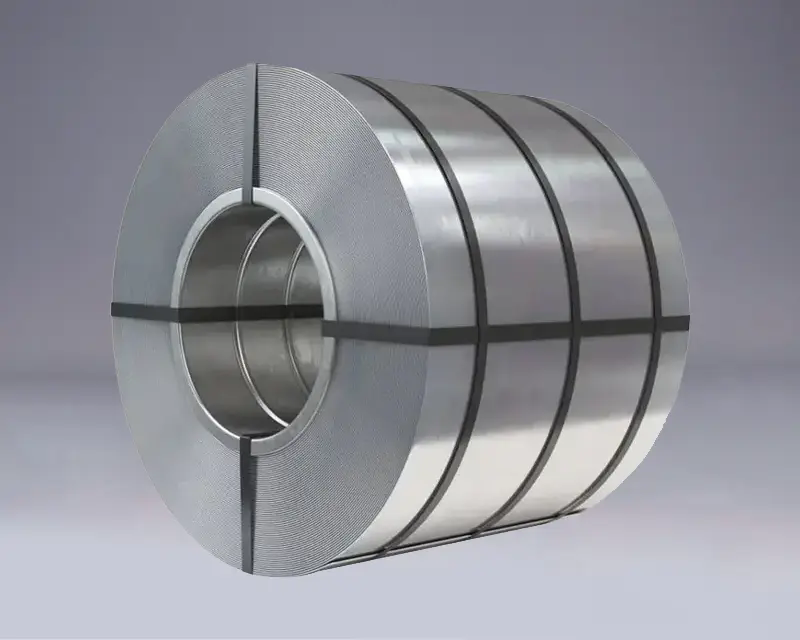

Cold Rolled Steel Coil – Precision and Quality for Advanced Applications

2025-07-24

Cold Rolled Steel Coil is a type of steel product processed at room temperature to achieve superior surface finish, dimensional accuracy, and enhanced mechanical properties. Unlike hot rolled steel, cold rolled steel coils are thinner, stronger, and have a smooth, shiny appearance, making them ideal for precision engineering and manufacturing.

Key Features

Superior Surface Finish:Smooth and clean surface suitable for painting and coating without additional preparation.

Tight Tolerances:Precise thickness control and flatness for applications demanding accuracy.

Improved Strength:Enhanced yield and tensile strength due to strain hardening from cold rolling.

Better Formability:Ideal for bending, stamping, and deep drawing processes.

Consistent Quality:Uniform microstructure and mechanical properties.

Common Grades and Materials

Cold rolled low carbon steel (e.g., DC01, DC03)

Cold rolled stainless steel (e.g., 304, 316)

High-strength cold rolled alloys

Typical Applications

Automotive body panels and components

Household appliances

Metal furniture

Electrical cabinets and enclosures

Construction and architectural panels

Precision tubes and pipes

Available Specifications

Thickness: 0.2 mm to 3.0 mm (customizable)

Width: up to 1500 mm or more

Coil weight: as per customer requirements

Surface treatment: Pickled, oiled, or coated

Advantages Over Hot Rolled Steel

Enhanced surface quality with no scale or mill marks

Closer dimensional accuracy for critical engineering uses

Superior mechanical properties suited for complex forming

Cold Rolled Steel Coil is the material of choice when quality, precision, and finish matter. Its versatility and excellent mechanical properties make it indispensable across many industries.