Key Components of Hot Runner PET Preform Molds

2024-06-15

Hot runner systems for PET preform molds are crucial in the production of PET preforms, which are used to manufacture PET bottles and containers. These systems ensure efficient and consistent injection molding, resulting in high-quality preforms. Here’s a detailed overview of hot runner systems, PET preform molds, their components, benefits, and applications:

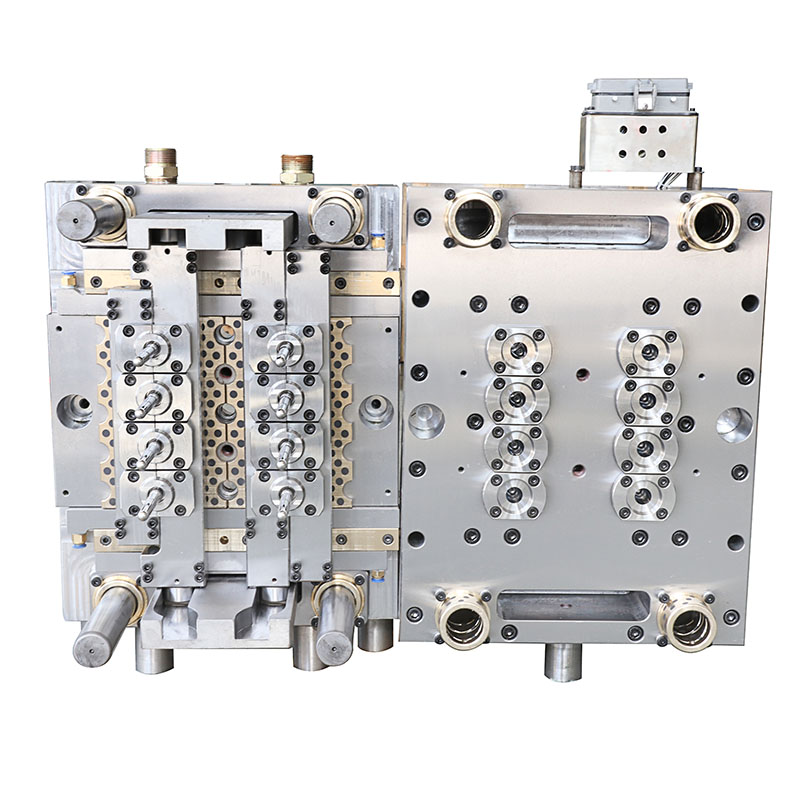

Key Components of Hot Runner PET Preform Molds

1. Hot Runner System:

- Manifold: Distributes the molten PET material evenly to multiple cavities. It maintains a consistent temperature to ensure smooth flow.

- Nozzles: Direct the molten PET into the mold cavities. They are designed to prevent heat loss and ensure precise delivery of material.

- Heaters: Maintain the temperature of the manifold and nozzles, ensuring that the PET remains molten throughout the injection process.

- Temperature Controllers: Regulate the temperature of the manifold and nozzles to prevent overheating or underheating.

2. Mold Base:

- Core and Cavity Plates: The core forms the inside of the preform, and the cavity forms the outside. These are precision-engineered to produce accurate preforms.

- Ejector System: Ejects the finished preforms from the mold cavities after they have cooled and solidified.

- Cooling System: Channels within the mold base that circulate coolant to rapidly cool the preforms and minimize cycle times.

3. Preform Design Specifics:

- Cavity Count: PET preform molds can range from a few cavities to several hundred, depending on production needs.

- Neck Finish: Different neck finishes are designed based on the intended use of the PET bottles, such as for carbonated drinks, water, or other beverages.

Benefits of Hot Runner Systems in PET Preform Molding

1. Improved Efficiency:

- Faster Cycle Times: By maintaining consistent temperature and eliminating the need to reheat solidified PET, hot runner systems significantly reduce cycle times.

- Less Waste: No runners or sprues are produced, minimizing material waste and reducing post-processing steps.

2. Higher Quality Preforms:

- Consistent Quality: Ensures uniform material flow and temperature, resulting in preforms with consistent weight, wall thickness, and clarity.

- Reduced Defects: Minimizes issues such as flow lines, air pockets, and uneven cooling, which can lead to defects in the final product.

3. Cost-Effectiveness:

- Material Savings: Reduced material waste translates into cost savings.

- Energy Efficiency: More efficient use of energy compared to cold runner systems, as less energy is required to maintain the temperature of the PET.

4. Design Flexibility:

- Customizable: Hot runner systems can be tailored to produce preforms of various sizes, shapes, and weights, catering to diverse packaging requirements.

Applications

- Beverage Industry: Producing preforms for water, soft drinks, juices, and alcoholic beverages.

- Food Packaging: Creating preforms for containers used in food packaging.

- Pharmaceutical and Personal Care: Manufacturing preforms for bottles used in pharmaceutical products and personal care items.

- Household and Industrial Products: Producing preforms for various household and industrial container applications.

Leading Brands and Manufacturers

1. Husky Injection Molding Systems:

- Known for their advanced hot runner systems and PET preform molds, providing high efficiency and quality.

2. SIPA (Societa’ Italiana di Produzione Automatica):

- Offers comprehensive solutions for PET preform production, including hot runner molds.

3. KraussMaffei:

- Provides innovative and reliable hot runner systems for PET preform molding.

4. Nissei ASB Company:

- Specializes in injection stretch blow molding machines and molds, including hot runner systems for PET preforms.

5. MHT Mold & Hotrunner Technology:

- Focuses on high-precision hot runner systems and molds for PET preform production.

Maintenance and Operation Tips

1. Regular Inspection: Check for wear and tear, and ensure all components are functioning properly.

2. Temperature Management: Maintain precise control of temperatures to prevent degradation of PET material and ensure consistent quality.

3. Cleaning and Lubrication: Regular cleaning and proper lubrication of moving parts to prevent sticking and ensure smooth operation.

4. Training: Ensure operators are well-trained in handling and maintaining the hot runner system and mold.

Conclusion

Hot runner PET preform molds are essential in the efficient and high-quality production of PET preforms. These systems offer significant advantages in terms of efficiency, quality, and cost-effectiveness, making them indispensable in industries that require large volumes of PET containers. By understanding the components, benefits, and proper maintenance of these systems, manufacturers can optimize their production processes and produce superior PET preforms to meet diverse market needs.