Key Points about CFRTP Sheets

2024-07-10

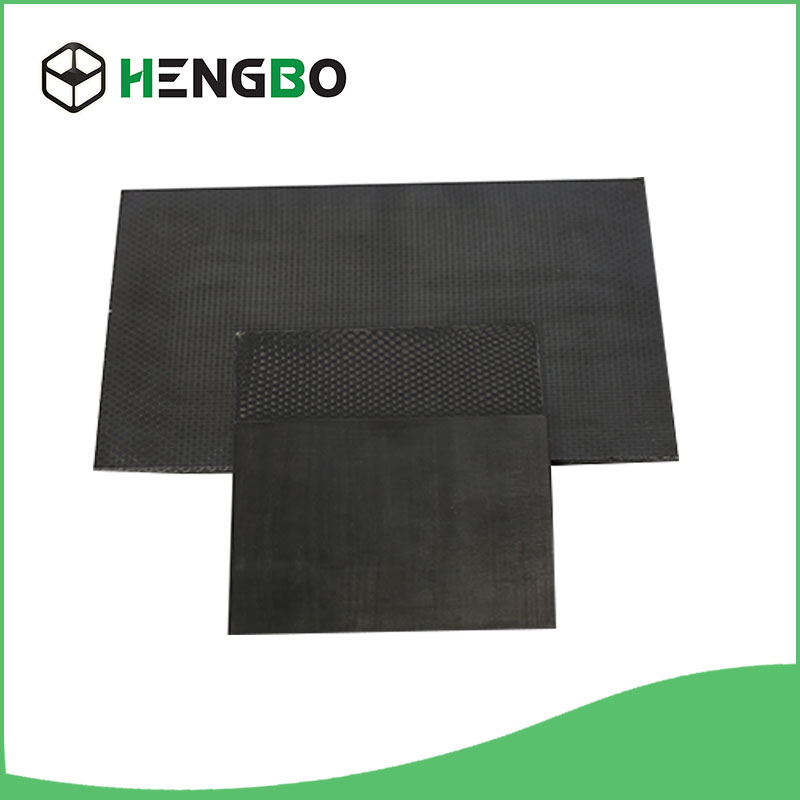

CFRTP stands for Continuous Fiber Reinforced Thermoplastic. CFRTP sheets are advanced composite materials made by impregnating continuous fibers (such as carbon fibers, glass fibers, or aramid fibers) into a thermoplastic resin matrix. Here are key points about CFRTP sheets:

Composition and Manufacturing

1. Continuous Fiber Reinforcement:

- Types of Fibers: Common fibers used include carbon fibers (for high strength and stiffness), glass fibers (for cost-effectiveness and moderate strength), and aramid fibers (for impact resistance and lightweight properties).

- Orientation: Fibers are aligned in a continuous, unidirectional, or woven pattern to provide strength and stiffness along specific directions.

2. Thermoplastic Matrix:

- Materials: Thermoplastic resins such as polypropylene (PP), polyethylene (PE), polyamide (PA), or polyetheretherketone (PEEK) are used.

- Processing: The resin matrix is melted and combined with the continuous fibers, then formed into sheets or laminates through processes like compression molding or extrusion.

Properties and Characteristics

1. High Strength-to-Weight Ratio:

- CFRTP sheets offer exceptional strength and stiffness compared to traditional materials like metals or standard thermoplastics.

- They are lightweight, making them suitable for applications where weight reduction is critical.

2. Impact Resistance and Durability:

- CFRTPs exhibit good impact resistance and durability, making them suitable for applications requiring toughness and resilience.

3. Chemical and Corrosion Resistance:

- Depending on the resin matrix used, CFRTP sheets can offer resistance to chemicals, moisture, and corrosion, enhancing their suitability for various environments.

4. Design Flexibility:

- CFRTP sheets can be tailored with specific fiber orientations, thicknesses, and resin formulations to meet application-specific requirements.

- They can be easily molded or formed into complex shapes, allowing for intricate designs and integration of functional features.

Applications

1. Automotive Industry:

- Used in automotive components such as structural panels, interior trim, and under-the-hood parts to reduce weight while maintaining strength and stiffness.

2. Aerospace and Defense:

- Applications include aircraft interiors, structural components, and UAV (unmanned aerial vehicle) parts due to their lightweight and high-performance properties.

3. Industrial Equipment:

- Used in machinery components, conveyor systems, and industrial housings where strength, durability, and resistance to wear are required.

4. Sports and Leisure:

- Found in sporting goods like tennis rackets, bike frames, and protective gear due to their lightweight and impact-resistant nature.

Advantages

1. Lightweight: Offers weight savings compared to traditional materials like metals, contributing to fuel efficiency in transportation applications.

2. Energy Efficiency: Enhanced mechanical properties contribute to improved energy efficiency in machinery and equipment.

3. Environmental Benefits: Can be recycled (depending on the resin used) and offer potential sustainability benefits through reduced material consumption and energy savings.

Challenges

1. Cost: Higher material and processing costs compared to conventional materials can be a barrier to widespread adoption.

2. Processing Complexity: Requires specialized equipment and expertise for manufacturing and processing CFRTP sheets, adding to production costs.

CFRTP sheets represent a cutting-edge material solution with a wide range of applications across industries where lightweight, high-strength, and durable materials are required. Ongoing advancements in materials science and manufacturing techniques continue to expand their potential uses and improve their performance characteristics.