Revolutionizing Manufacturing: The Rise of Smart Factories

2025-04-24

The concept of a smart factory is transforming the landscape of manufacturing across the globe. This innovative approach incorporates advanced technologies such as artificial intelligence (AI), the Internet of Things (IoT), robotics, and big data analytics into traditional manufacturing processes, creating a more efficient, flexible, and automated production environment. Smart factories are designed to operate with minimal human intervention, offering businesses the opportunity to optimize operations, reduce costs, and increase production quality.

One of the core elements of a smart factory is the use of connected devices that communicate with each other in real-time. This network of sensors, machines, and devices enables the factory to monitor operations continuously, collecting vast amounts of data that can be analyzed to improve performance. By using IoT technology, smart factories are able to track everything from equipment health to inventory levels, making it easier to identify issues before they escalate and improve overall operational efficiency.

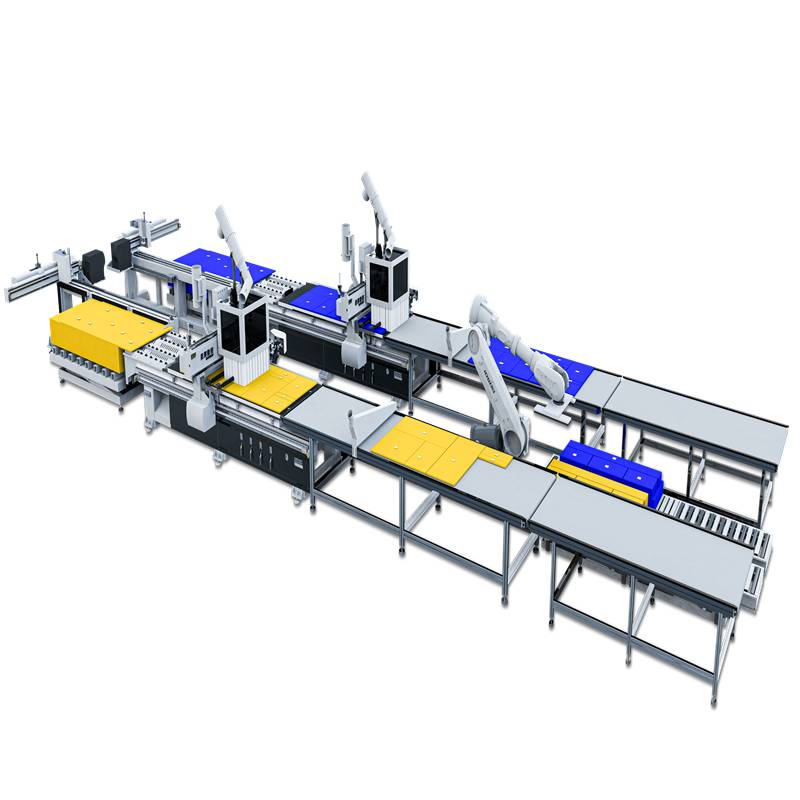

Automation is another key feature of smart factories. The use of robots and automated machinery helps reduce the need for manual labor, allowing for faster production times and more precise outputs. These systems can work tirelessly around the clock, reducing the risk of human error and ensuring that production runs smoothly. Automation also contributes to enhanced safety by taking over dangerous tasks, minimizing the chances of accidents in hazardous environments.

Data is at the heart of a smart factory’s operations. By gathering and analyzing data from various points in the manufacturing process, businesses can gain valuable insights into production trends, maintenance needs, and overall system performance. This data-driven approach helps manufacturers make more informed decisions, anticipate problems, and improve product quality. Predictive maintenance, for example, is a powerful tool that allows factories to foresee when machines will require servicing, avoiding costly breakdowns and minimizing downtime.

The integration of AI and machine learning further enhances the capabilities of smart factories. These technologies enable systems to learn from data and make autonomous decisions based on patterns and trends. AI algorithms can optimize production schedules, identify inefficiencies, and even adapt to changing conditions in real-time. This adaptability is crucial in industries where demand fluctuates frequently, allowing factories to remain agile and responsive to market needs.

Sustainability is another important consideration for smart factories. With a growing emphasis on environmental responsibility, many smart factories incorporate energy-efficient technologies and sustainable practices. Energy consumption can be closely monitored, and systems can be adjusted to minimize waste. Furthermore, smart factories can optimize the use of raw materials, reducing waste and improving resource efficiency.

The impact of smart factories extends beyond just the production line. They play a crucial role in the overall supply chain by providing real-time visibility into inventory levels, order fulfillment, and delivery status. This transparency helps businesses respond more quickly to customer demands, improve lead times, and streamline logistics. Additionally, smart factories enable more personalized products, as flexible manufacturing systems can accommodate customized orders without disrupting the overall production process.

Despite the many advantages, the implementation of smart factories comes with challenges. The initial cost of upgrading to smart technologies can be significant, and small to medium-sized businesses may find it difficult to justify the investment. There is also the issue of cybersecurity, as the increased connectivity of devices opens up potential vulnerabilities. Protecting sensitive data and ensuring secure communication between devices is essential to maintain the integrity of the factory’s operations.

Moreover, the transition to a smart factory requires a shift in workforce skills. Employees must be trained to operate and maintain the new technologies, as traditional roles in manufacturing evolve. This calls for a focus on upskilling workers, ensuring they can adapt to the changing demands of the industry. While automation reduces the need for some manual labor, it also creates opportunities for higher-skilled jobs in technology, data analysis, and system maintenance.

The potential of smart factories to revolutionize manufacturing is vast. By embracing these technologies, businesses can improve efficiency, reduce costs, and produce higher-quality products. As more manufacturers adopt smart factory principles, the way we think about production will continue to evolve, with smart factories becoming the backbone of modern manufacturing and setting the standard for industries worldwide.