The Importance of Medical Clinic Sealing Machines: Ensuring Safety and Efficiency

2024-10-18

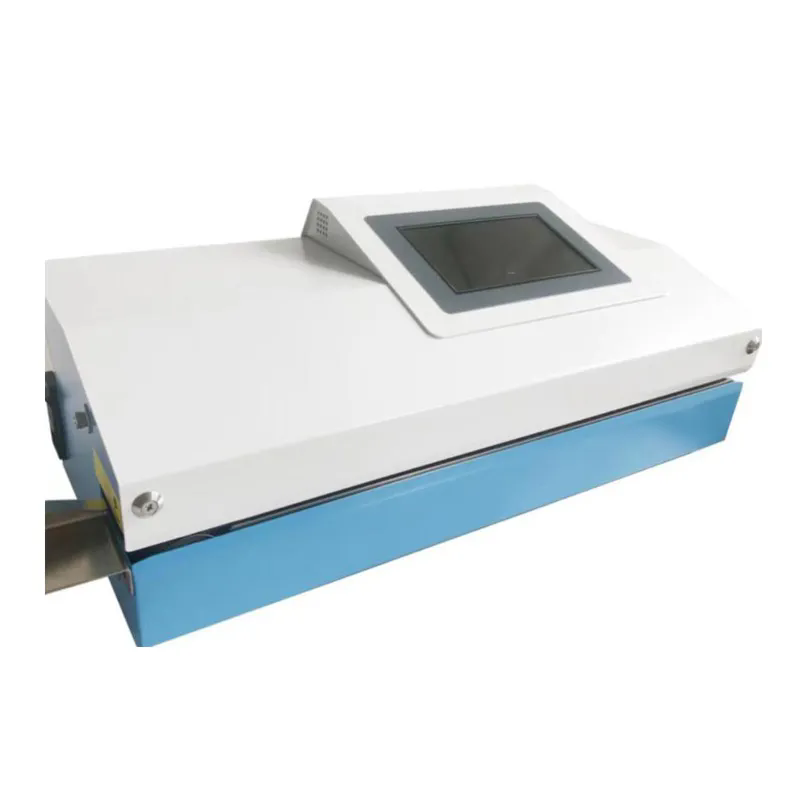

In the healthcare industry, the importance of maintaining hygiene and safety standards cannot be overstated. Medical clinics and hospitals handle sensitive materials and equipment that must remain sterile and uncontaminated. One crucial tool in this process is the medical clinic sealing machine. In this blog, we will explore the function and significance of sealing machines in medical settings, their types, benefits, and best practices for use.

What is a Medical Clinic Sealing Machine?

A medical clinic sealing machine is a specialized device used to seal medical packaging, such as bags, pouches, and containers, to ensure the sterility and integrity of their contents. These machines utilize heat, pressure, or adhesive to create airtight seals, preventing contamination from external sources.

The sealing process is essential for maintaining the quality of medical supplies, instruments, and pharmaceuticals, ensuring they remain safe for use in patient care.

Types of Medical Clinic Sealing Machines

1. Heat Sealers:

- Heat sealers are the most common type of sealing machines used in medical clinics. They work by applying heat to thermoplastic materials, creating a strong bond between the two surfaces. Heat sealers can be manual or automatic and come in various configurations, such as impulse sealers and continuous sealers.

2. Vacuum Sealers:

- Vacuum sealing machines remove air from packaging before sealing, creating a vacuum environment that helps extend the shelf life of medical products. These are particularly useful for packaging sensitive items that can be damaged by exposure to air.

3. Ultrasonic Sealers:

- Ultrasonic sealing machines utilize high-frequency sound waves to generate heat, which seals the packaging materials. This method is effective for various materials, including plastic films and nonwoven fabrics, and is often used for delicate items.

4. Pressure Sealers:

- These machines use pressure to create seals without the need for heat. Pressure sealers are typically used for packaging items that cannot withstand high temperatures.

Benefits of Using Medical Clinic Sealing Machines

1. Ensured Sterility:

- Sealing machines create airtight packaging that prevents contamination, helping to maintain the sterility of medical supplies and equipment until they are needed.

2. Increased Efficiency:

- Automated sealing machines can significantly speed up the packaging process in medical clinics, allowing for quick preparation of supplies without compromising safety.

3. Reduced Waste:

- By sealing items securely, these machines minimize the risk of damage or contamination, reducing waste and the need for repackaging.

4. Improved Inventory Management:

- Properly sealed items can be stored for extended periods, helping clinics manage their inventory more effectively and ensure they always have necessary supplies on hand.

5. Compliance with Regulations:

- Medical facilities are subject to strict regulations regarding the packaging and storage of medical supplies. Sealing machines help clinics comply with these standards, reducing the risk of regulatory violations.

Best Practices for Using Medical Clinic Sealing Machines

1. Regular Maintenance:

- To ensure optimal performance, regularly maintain and service sealing machines according to the manufacturer’s guidelines. This includes cleaning, checking seals, and replacing worn parts.

2. Training Staff:

- Provide comprehensive training for staff members on the proper use and operation of sealing machines. This ensures that employees understand the importance of the sealing process and how to use the equipment effectively.

3. Quality Control:

- Implement quality control measures to regularly check the integrity of sealed packages. This includes testing seals for strength and inspecting packages for signs of contamination.

4. Use Appropriate Materials:

- Always use packaging materials that are compatible with the sealing machine and appropriate for the items being sealed. Ensure that materials meet industry standards for sterility and safety.

5. Documenting Processes:

- Maintain thorough documentation of the sealing process, including dates, batch numbers, and any issues encountered. This documentation is essential for traceability and compliance with regulatory standards.

Conclusion

Medical clinic sealing machines play a vital role in maintaining hygiene and safety in healthcare environments. By ensuring the sterility of medical supplies and equipment, these machines contribute to improved patient care and operational efficiency.

Investing in quality sealing machines, along with proper training and maintenance, can enhance the overall performance of a medical clinic. As the healthcare industry continues to evolve, the importance of effective packaging solutions will remain paramount in providing safe and reliable patient care.