Understanding Round Condenser Tubes: Essential Components for Efficient Heat Exchange

2025-01-04

In industrial applications, especially in HVAC systems, power plants, and various cooling processes, the importance of effective heat exchange cannot be overstated. Among the many components that contribute to a well-functioning system, the round condenser tube plays a crucial role in ensuring efficient heat transfer. This blog will explore the function, benefits, and various uses of round condenser tubes, shedding light on why they are an integral part of many heat exchange systems.

What is a Round Condenser Tube?

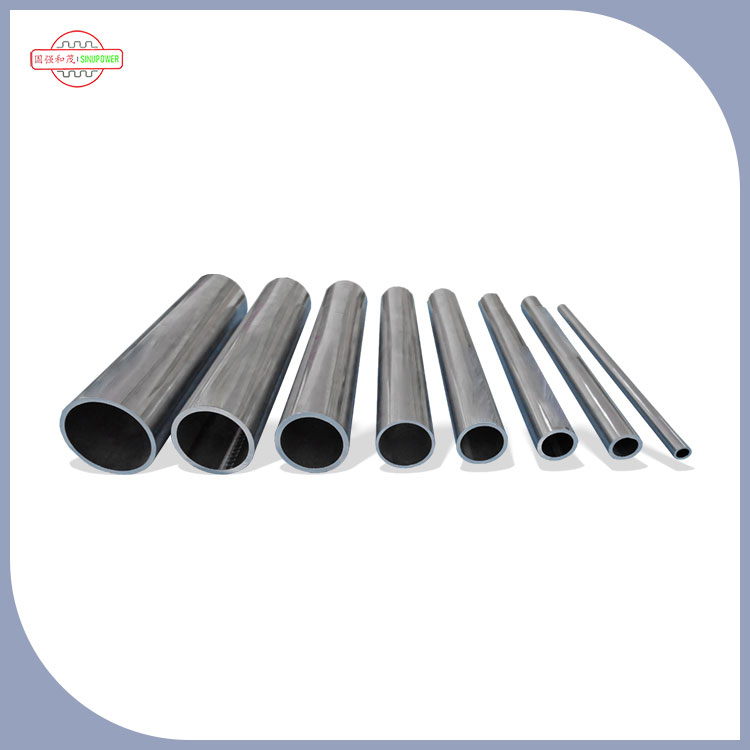

A round condenser tube is a cylindrical tube used in heat exchangers to facilitate the transfer of heat between two fluids. Typically made from materials like copper, aluminum, or stainless steel, these tubes are designed to allow one fluid to flow inside while another fluid flows around the exterior. This configuration promotes heat transfer through the walls of the tube, allowing the fluids to exchange heat efficiently.

In cooling towers, refrigeration systems, and condensers used in power plants, these tubes are used to cool down hot gases or liquids by transferring heat to a secondary coolant, such as water or air. The round shape of the tube allows for a high surface area in contact with the surrounding fluid, maximizing the efficiency of the heat transfer process.

How Do Round Condenser Tubes Work?

The operation of a round condenser tube is based on the principle of heat exchange. Here's how it typically works:

1. Fluid Flow: In a typical condenser system, hot gases or liquids (such as refrigerants or exhaust gases) are passed through the interior of the round condenser tubes. A cooling fluid, usually water, flows around the outside of these tubes.

2. Heat Transfer: As the hot fluid inside the tube travels, it releases its heat to the cooler surrounding fluid. The heat from the inner fluid is transferred through the walls of the tube to the cooler outer fluid.

3. Condensation: As heat is lost, the inner fluid condenses or cools down, depending on the system. For example, in refrigeration systems, the refrigerant cools and condenses into a liquid form after releasing heat.

4. Efficient Cooling: By utilizing the large surface area of the round tube, heat transfer occurs more efficiently, ensuring that the condenser system operates optimally and helps maintain the overall temperature of the system.

Benefits of Round Condenser Tubes

Round condenser tubes offer several advantages that make them highly effective and popular in industrial applications. Here are some key benefits:

1. Efficient Heat Transfer

The round shape of these tubes maximizes surface area for heat transfer. This design ensures that the hot fluids inside the tubes are exposed to the cooling fluid on the outside, allowing heat to dissipate quickly and efficiently. As a result, the heat exchanger works effectively, lowering the temperature of the system and improving the overall performance of the equipment.

2. Durability and Corrosion Resistance

Round condenser tubes are typically made from materials that are resistant to corrosion, such as stainless steel or copper. This makes them highly durable and capable of withstanding harsh operating environments, such as high temperatures, humidity, and chemical exposure. With proper maintenance, these tubes can last for many years without deteriorating.

3. Space Efficiency

The cylindrical design of the tube allows for a compact arrangement in condenser units, enabling heat exchangers to be more space-efficient. This makes round condenser tubes ideal for systems where space is limited but efficient cooling is essential.

4. Improved Flow Dynamics

The smooth, continuous inner surface of the round tube promotes laminar flow, reducing turbulence that could otherwise disrupt the heat exchange process. This smooth flow helps maintain an even transfer of heat, preventing hotspots and ensuring more uniform cooling.

5. Versatility

Round condenser tubes are versatile and can be used in a wide range of industries, including HVAC, power plants, refrigeration, and chemical processing. Whether cooling air, gas, or liquid, these tubes offer the adaptability needed for various thermal management applications.

Applications of Round Condenser Tubes

Round condenser tubes are found in many industries where heat exchange is critical. Here are some of the most common applications:

1. Power Plants

In power generation, round condenser tubes are used in the condenser units that cool the steam produced during the generation process. These systems help to convert steam back into water, which can then be reused in the system. Efficient cooling through the condenser tubes is essential to maintaining the plant's thermal efficiency.

2. HVAC Systems

Round condenser tubes are commonly used in air conditioning and refrigeration systems. They help cool refrigerants after they have absorbed heat from the environment, ensuring that the system can continue to run efficiently and maintain the desired temperature.

3. Chemical Processing

In many chemical plants, condensers are used to cool and condense vaporized chemicals back into their liquid form. Round condenser tubes are ideal for this purpose due to their ability to withstand high-pressure and high-temperature conditions while maintaining efficient heat transfer.

4. Marine Applications

In marine vessels, round condenser tubes are used to cool the engine coolant or to condense the exhaust gases. They ensure that the engine remains at an optimal temperature, preventing overheating and ensuring the smooth operation of the vessel.

5. Food and Beverage Industry

In the food and beverage industry, heat exchangers with round condenser tubes are used for processes like pasteurization, cooling of liquids, and refrigeration. Their efficiency is crucial for maintaining product quality and reducing energy consumption.

Types of Materials Used for Round Condenser Tubes

The choice of material for round condenser tubes depends on factors such as temperature, pressure, and the type of fluid being used. Here are some common materials:

1. Copper

Copper is a highly efficient heat conductor and is commonly used for round condenser tubes in refrigeration and HVAC systems. It is also corrosion-resistant, making it ideal for long-term use in cooling systems. However, copper is more expensive compared to other materials.

2. Stainless Steel

Stainless steel is another popular material for round condenser tubes. It is highly resistant to corrosion, particularly in harsh environments where chemicals or saltwater are present. Stainless steel is widely used in industries like chemical processing and marine applications.

3. Aluminum

Aluminum is a lightweight and cost-effective option for condenser tubes. It offers good heat transfer properties and is often used in applications where weight is a concern, such as in automotive or portable air conditioning systems.

4. Titanium

For applications that involve highly corrosive fluids or environments, titanium round condenser tubes are sometimes used. While more expensive, titanium is incredibly resistant to corrosion and has excellent heat exchange properties, making it ideal for specialized industries like marine and petrochemical sectors.

Conclusion

Round condenser tubes are essential components for efficient heat transfer in a variety of industrial applications. From power plants to HVAC systems and chemical processing, these tubes play a vital role in maintaining temperature control, reducing energy consumption, and extending the lifespan of equipment. With their durable materials, efficient heat exchange properties, and versatility, round condenser tubes continue to be an indispensable part of many heat exchange systems, ensuring smooth and reliable operations across industries.

Understanding the importance of these tubes and their various applications can help businesses choose the right materials and systems for their specific needs, ensuring both efficiency and longevity in their operations. Whether you're working in a power plant, a refrigeration unit, or a chemical plant, round condenser tubes are critical to achieving optimal heat exchange performance.