Understanding Thermal Lamination Film: Protecting and Enhancing Your Printed Materials

2025-01-04

In today's fast-paced world, protecting and enhancing printed materials is more important than ever. Whether it's a book, brochure, menu, or business card, first impressions matter. This is where thermal lamination film comes in. Widely used in the printing industry, thermal lamination film offers a cost-effective way to add durability, protection, and a professional finish to your printed materials.

In this blog, we’ll explore what thermal lamination film is, how it works, its benefits, and why it’s a go-to solution for businesses looking to extend the life and improve the appearance of their printed products.

What is Thermal Lamination Film?

Thermal lamination film is a type of protective coating that is applied to printed materials using heat and pressure. Unlike traditional laminating films that require adhesives, thermal lamination relies on a heat-sensitive layer that activates when exposed to a heated roller or press.

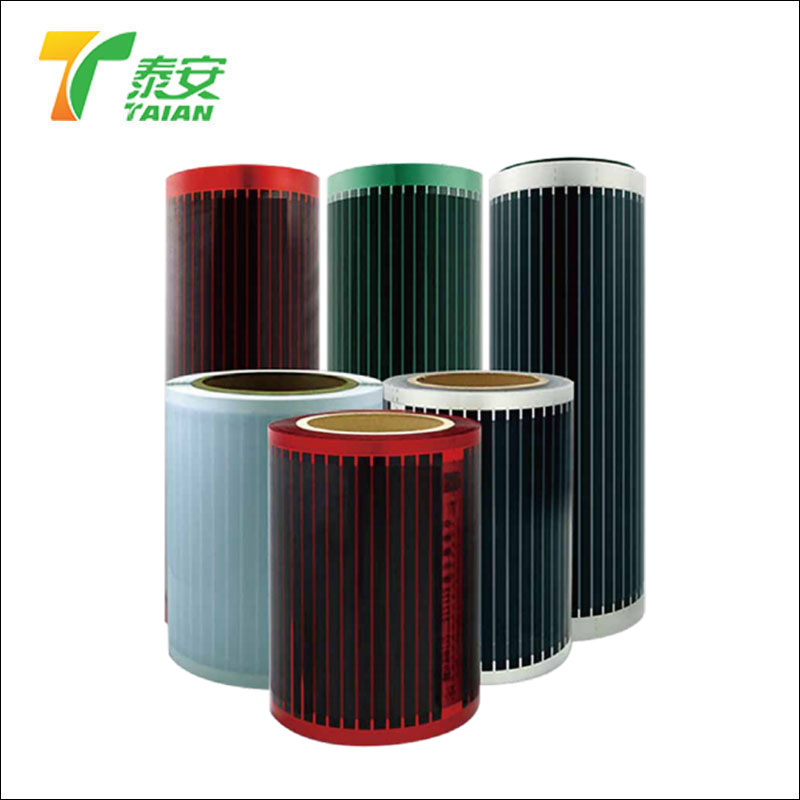

This film is available in a variety of finishes, including gloss, matte, and satin, allowing businesses to choose the most suitable option for their brand and product type. Once applied, the lamination adds a smooth, glossy, or matte protective layer to the surface of printed materials, making them more resistant to wear, tear, and environmental factors such as moisture, dirt, and UV rays.

How Does Thermal Lamination Film Work?

The process of applying thermal lamination film involves several steps, which are usually carried out using a thermal laminating machine. Here’s a simple breakdown of how it works:

1. Film Preparation: Thermal lamination film is pre-coated with a heat-sensitive adhesive that is activated by heat. The film is loaded into a laminating machine, and the printed material to be laminated is prepared.

2. Lamination Process: The printed material is passed through the laminating machine, where it is exposed to heat and pressure. The heat activates the adhesive layer on the thermal film, which then bonds with the printed material, creating a protective layer on its surface.

3. Cooling and Trimming: After the lamination is complete, the material is cooled, solidifying the bond between the film and the print. Any excess film is trimmed to ensure the finished product is neat and professional.

Types of Thermal Lamination Film

Thermal lamination film comes in different types, each offering unique properties and benefits. The three most common types of thermal lamination film are:

1. Glossy Lamination

Glossy thermal lamination film provides a shiny, reflective finish that enhances the colors and contrasts of the printed material. This finish is ideal for materials that need to grab attention, such as brochures, flyers, posters, and product packaging. It adds a vibrant, high-impact look, making the colors appear more vivid and sharp.

2. Matte Lamination

Matte thermal lamination film offers a smooth, non-reflective finish that gives printed materials a sophisticated, elegant appearance. It reduces glare, making it perfect for items like menus, business cards, and other materials that require a more subtle, professional look. Matte finishes are also more resistant to fingerprints, making them ideal for high-touch items.

3. Satin Lamination

Satin thermal lamination film is a combination of gloss and matte. It provides a low-sheen finish that delivers a premium, soft feel while still allowing the colors to pop. This finish is often used for high-end promotional materials, photo albums, and marketing collateral where a luxurious touch is desired.

Benefits of Thermal Lamination Film

Thermal lamination film offers numerous advantages for businesses looking to enhance their printed materials. Some of the key benefits include:

1. Durability and Protection

One of the primary reasons people choose thermal lamination is its ability to protect printed materials from wear and tear. The lamination acts as a barrier against moisture, dirt, scratches, and fading, which helps preserve the appearance of the print over time. This is especially important for items like brochures, menus, or educational materials that are handled frequently.

2. Enhanced Appearance

Laminating printed materials with thermal film can greatly enhance their visual appeal. Glossy finishes can make colors more vibrant, while matte and satin finishes provide a smooth, sophisticated appearance. The lamination also helps to smooth out any imperfections on the surface of the print, giving it a professional, polished look.

3. Increased Longevity

Lamination helps extend the lifespan of printed materials, which is especially useful for items that will be stored or displayed for extended periods. By providing a layer of protection, thermal lamination ensures that prints stay in good condition even after years of handling or exposure to environmental factors like humidity and sunlight.

4. Water and Smudge Resistance

One of the biggest advantages of thermal lamination is its resistance to water, stains, and smudges. The film acts as a waterproof barrier, making it easier to wipe off spills or dirt without damaging the printed material underneath. This feature is particularly useful for items like menus, outdoor signage, or product packaging that are exposed to moisture or frequent handling.

5. Cost-Effective

Thermal lamination is a relatively inexpensive way to enhance the quality and durability of printed materials. It’s more affordable than many other methods of coating, such as UV coating or varnishing, and can be done quickly, making it an ideal solution for businesses on a budget.

6. Eco-Friendly Options

Many manufacturers offer eco-friendly thermal lamination films made from biodegradable or recyclable materials. These sustainable options help businesses reduce their environmental impact while still enjoying the benefits of lamination.

Applications of Thermal Lamination Film

Thermal lamination film is used across a variety of industries and applications. Some of the most common uses include:

1. Marketing and Promotional Materials

Thermal lamination is often used for brochures, flyers, and catalogs to give them a professional, durable finish that holds up in high-traffic environments. A glossy finish can make the colors pop, while matte options give a sophisticated, tactile appeal to the printed material.

2. Business Cards

Business cards laminated with thermal film not only look sleek and professional, but they also resist fading, tearing, and staining. The laminate provides extra protection against moisture and handling, ensuring the cards maintain their pristine condition for longer.

3. Menus

Restaurants and cafes frequently use thermal lamination for their menus. A laminated menu resists food and drink spills, stains, and creases, ensuring it remains clean and presentable throughout daily use.

4. Educational Materials

Books, flashcards, and other educational materials benefit greatly from thermal lamination. The added durability ensures that materials can withstand heavy usage, and the protection helps preserve them for longer periods, reducing replacement costs.

5. Packaging

Thermal lamination is often used for product packaging, such as box covers, labels, and pouches. It gives the packaging a glossy, high-quality finish while offering protection from moisture and environmental factors.

6. Photographs and Art Prints

Laminating photographs or artwork with thermal film provides a protective coating that preserves the quality of the images. It helps prevent fading and keeps the prints looking fresh for years.

Conclusion

Thermal lamination film is an essential tool for businesses looking to protect and enhance their printed materials. From increasing durability and longevity to improving the overall appearance, thermal lamination offers numerous benefits for a wide range of applications. Whether you're creating marketing materials, business cards, menus, or educational content, thermal lamination is an affordable, effective solution that will help ensure your prints stand out while lasting longer.

With its versatility, cost-effectiveness, and ability to enhance both the functionality and aesthetic appeal of your printed materials, thermal lamination is a must-have in the toolkit of anyone involved in the printing industry.