What Makes PCB Assembly Crucial for Modern Electronics?

2024-12-26

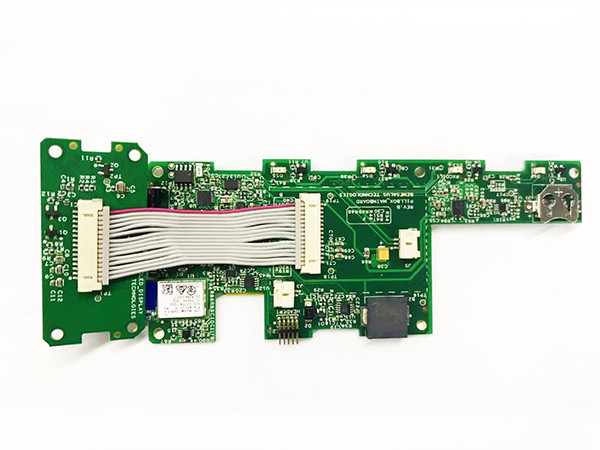

In today’s fast-paced, technology-driven world, printed circuit boards (PCBs) are the backbone of most electronic devices. From smartphones to medical equipment, PCBs play a critical role in ensuring that electrical components work together seamlessly. But how exactly does the process of PCB assembly contribute to the functionality and efficiency of modern electronics? Let’s dive into why PCB assembly is so crucial in the design and production of electronic devices.

1. What Is PCB Assembly?

PCB assembly is the process of soldering various electronic components onto a printed circuit board, which is the foundation of most modern electronic devices. These components can include resistors, capacitors, diodes, integrated circuits (ICs), and connectors, which are essential for the functioning of the device.

The assembly process typically involves the following key steps:

- Soldering: Components are attached to the PCB using a soldering process, which can be either wave soldering or reflow soldering. This step ensures that the components are firmly connected to the board, establishing the necessary electrical connections.

- Component Placement: The components are precisely placed on the PCB according to the design, either by hand or through automated machines, ensuring that the board functions correctly.

- Inspection and Testing: Once the assembly is complete, the PCB is thoroughly tested for defects, such as poor solder joints or incorrect component placement. This step ensures the quality and reliability of the board before it is used in electronic devices.

2. Why Is PCB Assembly Important for Electronics?

PCB assembly is an essential part of the manufacturing process of any electronic device, and here’s why:

- Reliability and Durability: Properly assembled PCBs ensure that the device operates smoothly and reliably for an extended period. The accuracy of the assembly process determines the longevity and durability of the electronic device. If the components are not assembled correctly, the device may malfunction, leading to performance issues or even failure.

- Compact and Efficient Design: One of the key advantages of using PCBs is their ability to integrate complex circuits into a small, compact space. PCB assembly allows manufacturers to design more efficient, lightweight, and space-saving electronic devices. This is especially important in the production of portable devices like smartphones and laptops.

- Cost-Effectiveness: Automated PCB assembly processes can significantly reduce production costs, making it easier for manufacturers to produce high-quality electronic devices at scale. By automating the soldering and component placement processes, PCB assembly ensures a higher level of precision and reduces the chances of human error, which can be costly.

- Customization for Different Applications: PCB assembly allows for customization based on the specific needs of the electronic device. Whether it's for consumer electronics, automotive systems, medical devices, or industrial machinery, the flexibility of PCB assembly enables the integration of specialized components for each application.

3. What Are the Different Types of PCB Assembly?

Depending on the complexity and requirements of the electronic device, PCB assembly can be categorized into different types:

- Through-Hole Technology (THT): This is the traditional method of PCB assembly where components have leads that are inserted into holes on the board and soldered on the other side. THT is ideal for components that require a strong mechanical bond, such as large capacitors and connectors.

- Surface-Mount Technology (SMT): In SMT, components are placed directly onto the surface of the PCB without the need for holes. This technology is more efficient and cost-effective, allowing for a higher density of components and smaller, lighter devices. SMT is widely used in modern electronics for its ability to accommodate smaller components and improve the overall design.

- Mixed Technology: Some PCBs may use both THT and SMT, depending on the components being used and the design requirements. Mixed technology can offer the benefits of both assembly methods, providing a balance between mechanical strength and compactness.

4. How Does PCB Assembly Impact the Performance of Electronics?

The quality of PCB assembly directly impacts the performance of the electronic device. Poor assembly can lead to a range of issues that can compromise the functionality of the device:

- Electrical Performance Issues: Incorrect placement of components or poor soldering can result in faulty connections, leading to electrical issues such as signal interference, short circuits, or power failure.

- Heat Management Problems: Electronics generate heat during operation, and proper PCB assembly ensures that components are arranged to optimize heat dissipation. A poorly assembled PCB may result in overheating, which can damage the components and reduce the lifespan of the device.

- Signal Integrity: Modern electronic devices often require high-speed signals to communicate between different parts of the system. If the PCB is not assembled correctly, it can result in signal loss, noise, or distortion, which can degrade the performance of the device.

5. What Are the Key Considerations for PCB Assembly?

When designing a PCB for assembly, several factors must be considered to ensure the success of the final product:

- Design for Manufacturability (DFM): A well-designed PCB should be easy to assemble with minimal complexity. DFM focuses on simplifying the design to reduce the chances of errors and improve the efficiency of the assembly process.

- Component Selection: Choosing the right components is essential for achieving the desired functionality and reliability of the device. The components must be compatible with the board layout and the intended application of the device.

- Quality Control: Rigorous testing and inspection are necessary to ensure that the PCB assembly is free from defects. Any issues, such as poor soldering, incorrect component placement, or damage to the board, must be identified and corrected before the PCB is used in the final product.

- Environmental Considerations: With the increasing demand for environmentally friendly electronics, it is important to use eco-friendly materials and processes in PCB assembly. This includes using lead-free solder and ensuring proper disposal of waste materials.

6. How Can PCB Assembly Be Improved for Future Technologies?

As technology continues to evolve, the demand for smaller, faster, and more efficient electronics grows. The future of PCB assembly will likely include the following advancements:

- Miniaturization: As devices continue to get smaller, PCB assembly will have to adapt to accommodate even smaller components and tighter layouts. Advances in microelectronics and flexible PCBs will play a significant role in the development of miniaturized devices.

- Advanced Materials: New materials, such as high-performance polymers and ceramics, will improve the thermal conductivity, durability, and electrical performance of PCBs. These materials can help address the challenges of next-generation electronic devices.

- Automated and AI-Assisted Assembly: The use of automation and artificial intelligence in the PCB assembly process will lead to faster, more precise manufacturing. AI-assisted systems can detect defects in real-time and optimize the assembly process, improving the overall quality and efficiency of PCB production.

Conclusion

In conclusion, PCB assembly is an integral part of the electronics manufacturing process. It ensures that electronic devices function efficiently, reliably, and sustainably. Whether you’re designing a consumer gadget, a medical device, or an industrial system, the quality of PCB assembly will directly affect the performance, durability, and cost-effectiveness of your product. As technology continues to advance, PCB assembly will play an even more vital role in shaping the future of electronics.