Why Are General Plastic Pellets Crucial for Modern Manufacturing?

2024-12-31

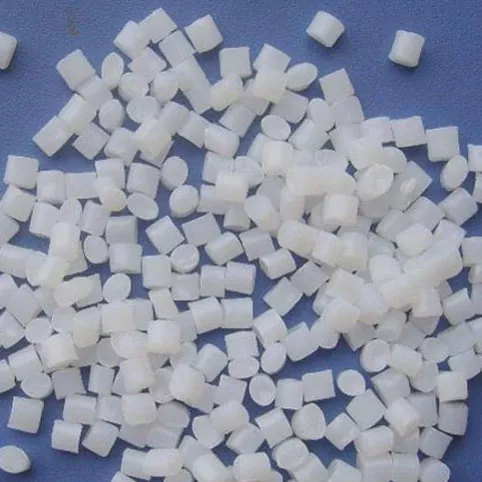

In the world of manufacturing, efficiency, consistency, and versatility are key factors for success. One material that plays a pivotal role in this process is general plastic pellets. But what exactly makes these small, often overlooked pellets so essential to modern production? Let's take a closer look at their importance and why they are a cornerstone of manufacturing across various industries.

What Are General Plastic Pellets?

General plastic pellets, also known as plastic resin pellets, are small, uniformly shaped plastic granules used as the raw material in the production of plastic products. These pellets are produced from various types of plastic resins, such as polyethylene, polypropylene, polystyrene, and others, depending on the intended application. They serve as the foundation for a wide range of manufacturing processes, including injection molding, extrusion, blow molding, and thermoforming.

Why Are General Plastic Pellets So Important?

General plastic pellets are more than just raw material—they are the building blocks of countless products we use every day. Here’s why they are so critical to modern manufacturing:

1. Consistent Quality

- Plastic pellets are manufactured to strict standards of size, shape, and composition, ensuring that they melt and flow uniformly during production. This consistency is essential for high-quality end products.

2. Versatility

- These pellets can be made from a variety of plastics, each offering different properties. Whether the goal is strength, flexibility, transparency, or chemical resistance, plastic pellets can be tailored to meet the specific needs of a product.

3. Efficiency in Production

- Plastic pellets streamline the manufacturing process. Their uniformity allows for easy handling, consistent melting, and faster production cycles, which ultimately improves manufacturing efficiency.

4. Cost-Effectiveness

- Using plastic pellets reduces waste and material costs. Their compact and easily stored form allows manufacturers to purchase and store large quantities without taking up excessive space, and they can be reused or recycled in many cases.

5. Environmental Benefits

- Many plastic pellets are recyclable, which aligns with the growing demand for sustainable manufacturing practices. As a result, plastic pellets play an important role in reducing waste and promoting circular economy practices.

Where Are General Plastic Pellets Used?

Plastic pellets are incredibly versatile and can be found in a wide array of applications:

- Packaging: Pellets are melted and molded into various types of packaging, such as bottles, containers, and plastic films.

- Automotive: Used to create components such as dashboard panels, bumpers, and door handles.

- Consumer Goods: Found in everything from toys and electronics to household items and furniture.

- Medical Devices: Many medical products, like syringes, IV bags, and surgical instruments, are made from plastics derived from pellets.

- Construction: Pellets can be used to produce pipes, insulation materials, and other construction-related products.

How Are General Plastic Pellets Made?

The production of plastic pellets involves several key steps:

1. Polymerization: The base plastic resin is created through a chemical process called polymerization, where smaller molecules are chemically bonded to form long chains.

2. Compounding: The resin is then blended with additives like colorants, stabilizers, and fillers, depending on the intended properties of the final product.

3. Pelletizing: The compounded plastic is extruded into long strands, which are then chopped into small, uniform pellets. These pellets are cooled and packaged for shipment to manufacturers.

Are There Any Challenges with Using General Plastic Pellets?

While plastic pellets are essential to manufacturing, there are some challenges that come with their use:

- Environmental Concerns: If not disposed of or recycled properly, plastic pellets can contribute to environmental pollution. Microplastic pollution, in particular, has become a growing concern.

- Quality Control: Although pellets are designed for consistency, variations in size, shape, or material quality can lead to manufacturing defects in the final product.

- Storage and Handling: Pellets need to be stored properly to avoid contamination, moisture absorption, or damage. Specialized handling procedures are often required to maintain their quality.

Conclusion

General plastic pellets may seem like small components, but they are the driving force behind a vast array of products that touch every aspect of our lives. Their consistency, versatility, and cost-effectiveness make them indispensable to the manufacturing process, enabling industries to create everything from packaging and automotive parts to medical devices and consumer goods.

As the world continues to innovate and focus on sustainability, plastic pellets will undoubtedly evolve to meet the changing needs of industries, ensuring that they remain a critical component in modern manufacturing.