Why Are Lock Washers Crucial for Secure Fastenings?

2024-11-21

When it comes to ensuring the integrity and safety of mechanical assemblies, the small components often make the biggest impact. One such component that plays a critical role is the lock washer. But why are lock washers so important, and how do they contribute to the stability of your fastening systems?

In this blog, we will explore the function, benefits, and different types of lock washers, as well as the industries that rely on them for secure connections.

What Are Lock Washers?

A lock washer is a type of washer that is specifically designed to prevent a fastener, such as a bolt or nut, from loosening due to vibration or torque. Unlike regular washers, lock washers have a unique design that creates additional friction and pressure when they are installed. This ensures that the fastener remains secure and doesn’t back out over time.

Lock washers come in a variety of designs, including split lock washers, tooth lock washers, and wave washers. Each type serves a specific purpose and can be selected depending on the requirements of the application.

Why Are Lock Washers So Important?

1. Prevent Fastener Loosening

The primary function of lock washers is to prevent fasteners from loosening. This is especially critical in applications where vibrations or dynamic forces can cause bolts and nuts to become undone over time. Without lock washers, fasteners are more likely to loosen, leading to potential equipment failure, safety hazards, and costly downtime.

2. Increase Friction and Grip

Lock washers are designed to increase friction between the fastener and the material it’s securing. This additional grip helps to resist the forces that may cause a fastener to turn or loosen. In high-torque or high-vibration environments, the extra friction is essential for maintaining a tight and secure connection.

3. Cost-Effective Solution

Lock washers are a relatively inexpensive solution to a potentially costly problem. When used properly, they can significantly extend the lifespan of fasteners and prevent the need for frequent maintenance or replacements. By preventing fastener loosening, lock washers help reduce the chances of damage to surrounding components and systems.

4. Easy to Install

Lock washers are easy to install, and they don’t require any special tools or skills. Once the fastener is tightened, the lock washer creates a mechanical interlock that keeps the fastener in place. This simplicity makes lock washers a reliable and user-friendly option for securing mechanical joints.

What Are the Different Types of Lock Washers?

1. Split Lock Washers

The most common type of lock washer, split lock washers are made from a single piece of material that is split and bent into a spiral shape. The ends of the washer are forced into the surface of the material being fastened, creating additional friction to prevent loosening.

2. Tooth Lock Washers

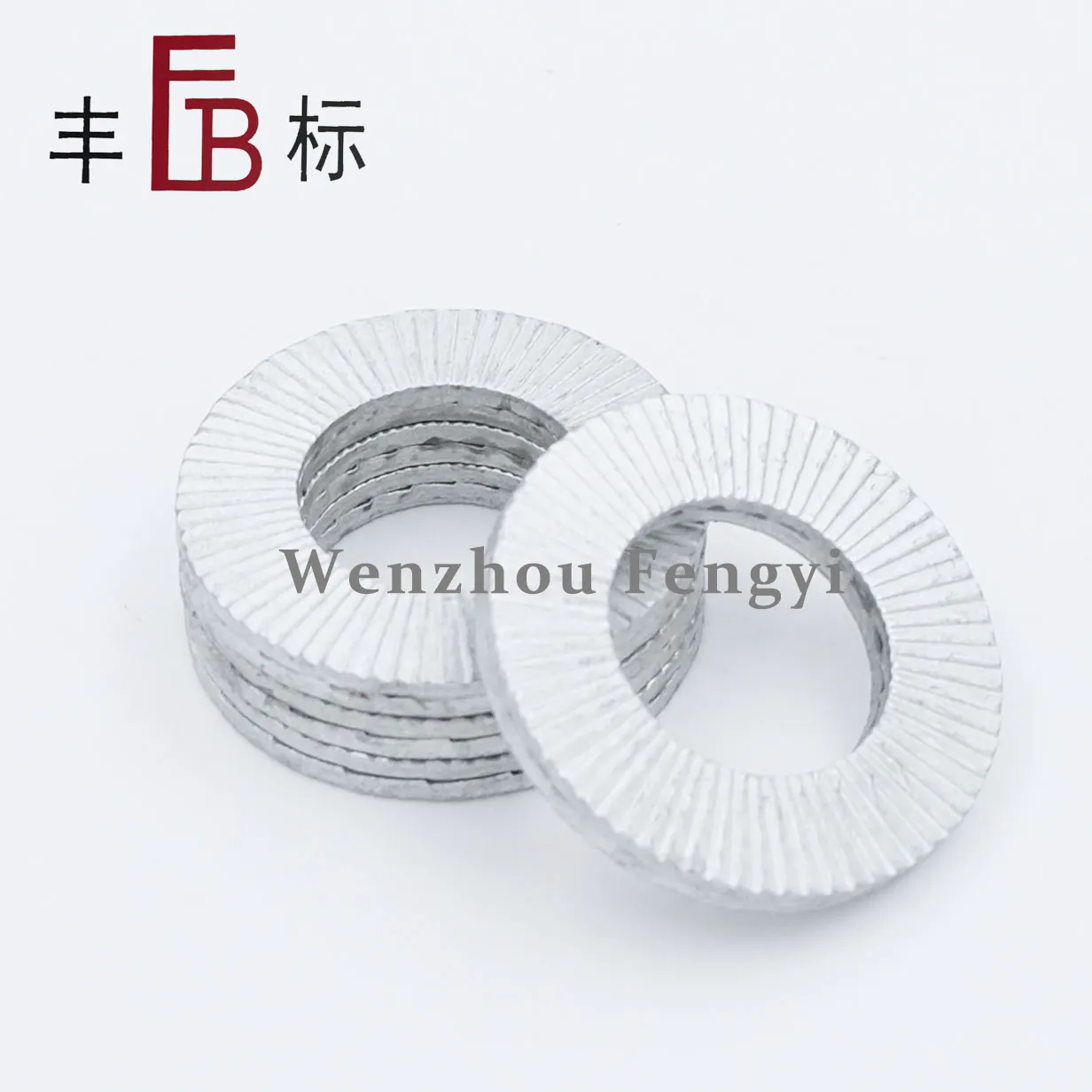

Tooth lock washers have teeth that are bent outward and engage with the surface of the fastener and the material it’s securing. The teeth create a strong mechanical interlock that resists loosening due to vibrations. These washers are especially useful in applications where high levels of torque or dynamic forces are present.

3. Wave Washers

Wave washers are designed with a wavy, flexible structure that allows them to absorb shock and provide a consistent load on the fastener. These washers are commonly used in applications where flexibility and cushioning are needed, such as in automotive and aerospace systems.

4. Spring Lock Washers

Spring lock washers are similar to split lock washers but are made from materials that provide additional spring-like tension. These washers exert a constant force on the fastener, keeping it secure in environments where there are varying temperatures or vibrations.

Where Are Lock Washers Used?

Lock washers are found in a wide range of industries, particularly in situations where the reliability and safety of fasteners are paramount. Some of the industries that commonly use lock washers include:

1. Automotive

In the automotive industry, lock washers are used to secure critical fasteners in engines, transmissions, and other mechanical systems. Vibrations from the engine or the road can loosen fasteners over time, but lock washers help to prevent this from happening, ensuring the vehicle remains safe and functional.

2. Aerospace

Aerospace applications require parts that can withstand extreme vibrations, pressure, and temperature changes. Lock washers are essential in ensuring that fasteners remain secure in aircraft, where even small component failures can lead to catastrophic consequences.

3. Manufacturing and Machinery

In industrial machinery, lock washers are used to secure bolts, nuts, and other fasteners that hold complex systems together. Whether in conveyor systems, presses, or robotics, these washers ensure that critical components stay in place, minimizing downtime and the risk of equipment failure.

4. Electronics

Lock washers also play a role in the electronics industry, especially in assemblies that involve heavy-duty connectors or other parts that may be subject to vibrations or thermal expansion. The washers help maintain electrical connections and prevent loosening, ensuring the reliability of electronic devices.

How Do Lock Washers Improve Safety and Reliability?

The importance of lock washers in terms of safety cannot be overstated. In critical applications, a fastener that loosens can lead to severe consequences, including equipment malfunction, safety hazards, and even accidents. Lock washers enhance the reliability of mechanical connections by ensuring that fasteners stay securely in place, even in the harshest operating conditions.

In addition to improving safety, lock washers contribute to overall system efficiency. When fasteners remain tight and secure, there is less risk of vibration-induced damage, leading to a longer lifespan for the components they are securing. This reduces the need for frequent maintenance and increases the overall reliability of the system.

Conclusion: Why Should You Use Lock Washers?

Lock washers are a simple yet highly effective solution for preventing fastener loosening, improving the safety and reliability of mechanical assemblies. Whether in automotive, aerospace, industrial machinery, or electronics, the role of lock washers is critical in ensuring that fasteners remain secure under various conditions.

By offering increased friction, preventing loosening, and providing an affordable solution to fastener failure, lock washers are indispensable components in modern manufacturing and mechanical design.